Time:2020-04-01 Reading:17475

Recently, a team led by Zhao Xuanhe, a professor in the Department of Mechanical Engineering at the Massachusetts Institute of Technology, successfuly made a conductive polymer that was originally a liquid into a toothpaste shaped 3D printing raw material, which retained the original conductive properties of the material while achieving 3D printing processing.

Zhao told DeepTech that the biggest breakthrough of the research is to propose a new processing and manufacturing method for conductive polymers, and realize the 3D printing of conductive polymers. In addition, compared with previous conductive polymer processing methods, this processing method has significantly improved the accuracy, while reducing the manufacturing cost and processing time by several orders of magnitude.

The results were published in the journal Nature Communications on March 30.

1. Conductive 'Liquid' makes conductive 'toothpaste'

Materials Conducting polymers, which are similar in flexibility to plastics and conduct electricity similar to metals, have gained much attention in recent years. These unique properties allow conducting polymers to be used in a wide range of applications, but at present there are significant bottlenecks in the process of manufacturing.

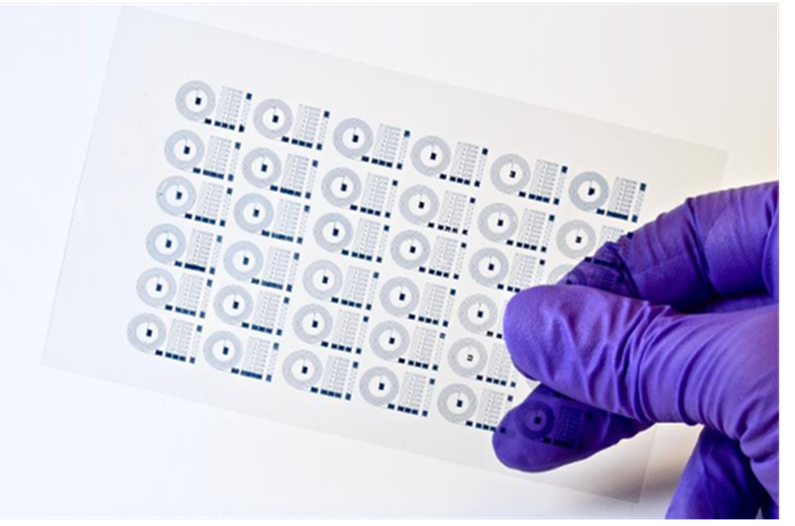

According to the team, these conductive polymers can easily be used as a coating to evenly spray the surface of the touch screen. However, it is difficult for existing manufacturing processes to achieve high-precision two-dimensional patterns over large areas, and it has never been possible to create complex three-dimensional structures through 3D printing.

If conductive polymers capable of 3D printing are developed, they could be used to print a large number of flexible electronic devices with diverse shapes and structures, such as flexible circuits and neural electrodes used in brain-computer interfaces.

According to reports, existing processing technologies for conductive polymers include: electron beam lithography (electron beam lithography), inkjet printing and similar methods of screen printing.

These methods have limitations: inkjet printing and screen printing can only produce two-dimensional conductive polymer devices with low precision; Electron beam etching can only achieve two-dimensional devices on a smaler scale and is expensive. Therefore, at present, the manufacturing and processing of conductive polymers is a key obstacle limiting the further development of this material.

Themanufacturing and processing problems are also the most critical breakthroughs in the latest research of Zhao Xuanxhe's team. People have tried to use 3D printing to manufacture conductive polymers before,but the problem is that conductive polymers are in a liquid state before preparation, the so -called"extrusion flows away", can not maintain the original form, which is the main reason for the failure of 3D printing before.

To realize 3D printing, a key step is to solve the problem of printing materials. "We've taken a liquid,conductive polymer and turned it into a toothpaste." Cho said. For the study, the team chose poly3, 4-vinyldioxythiophene/polystyrene sulfonate (PEDOT: PSS) -- a widely used conductive polymer, often in the form of a dark or dark blue liquid, whose nanofibers are key to the material's conductivity.

In order to feed the material into a 3D printer as a printing material, the team needed to find a way to"thicken" it without changing its own electrical conductivity.

They first froze and dried the water-like conductive polymer, leaving behind materials such as nanofibers,and then mixed the dried nanofibers with previously developed water and organic solvents to create a hydrogel that blends the nanofibers.

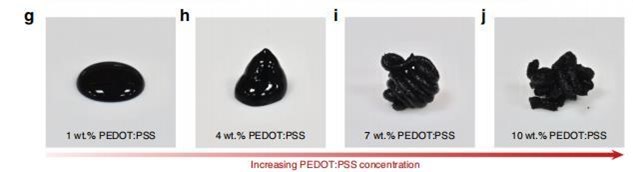

After comparison, it was found that when the nanofiber content in the hydrogel was between 5% and8%, the material became toothpaste-like in shape, suitable for 3D printing raw materials, to obtain a variety of high-precision, three-dimensional devices and structures, while also maintaining the conductivity of the conductive polymer itself.

FIG. | morphologies of the materials with different nanofiber content

This approach reflects Zhao's team's unique understanding of the structure and properties of the material.

"We finally found that during the freezing and drying of the material, the nanofibers in the conductive polymer aggregate and interact with each other, which ultimately gives the rheological properties required for use as 3D printing inks." Zhau explains.

2.A leap from two to three dimensions

In the process of using conductive polymers to create various components, Zhao Xuanhe said that the use of 3D printing methods can significantly improve the accuracy, cost and processing time compared with traditional processes.

According to reports, the currently widely used screen printing and inkjet printing technology can only print two-dimensional components, can not print three-dimensional multi-material components; At the same time, the processing accuracy of these two manufacturing methods is low, about one hundred microns, in contrast, 3D printing method can improve the accuracy to ten microns, and the future of this precision is possible to make further breakthroughs; Finaly, in terms of time, the traditional processing time may take several hours or even days, and now it only takes dozens of minutes to make the same device.

In addition to screen printing and inkjet printing, there are also high-precision manufacturing methods in the manufacture of conductive polymers - electron beam etching methods.

This method can improve the manufacturing accuracy to the micron level, but due to the complexity of the process and the need for ultra-clean room, the cost is very high. Neural probes, for example, can cost thousands or tens of thousands of dolars to manufacture using the etching method. The method proposed by Zhao's team could reduce the cost by several orders of magnitude.

However, Cho stressed that the most critical breakthrough was the zero to one breakthrough in printing3D conductive polymers.

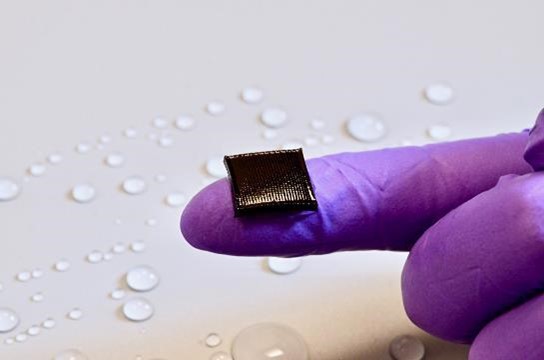

Not only that, these 3D printed conductive polymers can also be combined with other 3D printed materials,including 3D printed rubber or other 3D printed polymers, to form a multi-material 3D printed device, to achieve more application possibilities.

3. 3D printed flexible neural electrodes

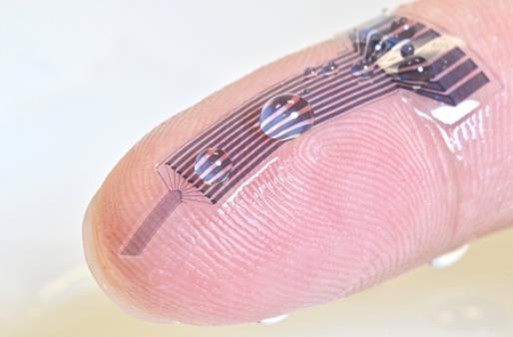

To verify the performance of the 3D printed conductive polymer, the team used the material to print a tiny rubber-like electrode, which is only 10 microns wide at its narrowest point, as a neural electrode for connecting animal brains to external devices in brain-computer interface applications. This size alows the electrode to receive electrical signals from a single neuron.

The team implanted the electrodes into the brains of mice. While the mice were moving freely, t he neural electrodes successfully received electrical signals from individual neurons. The results show that the material is expected to be an excellent material for neural electrodes in practical applications of brain-computer interfaces in the future.

FIG. | neural electrode

Brain-computer interface (BCI) refers to a direct connection pathway created between the brain of a human or animal and an external device to complete the exchange of information between the brain and the device. Invasive BCI is mainly used to reconstruct special senses (such as vision) and motor functions in paralyzed patients. Such BCI are usualy implanted directly into the grey matter of the brain.

However, the brain is one of the most fragile organs in humans, and brain implants are usually made of metal and other rigid materials. Over time, brain implants may cause damage, inflammation, immune responses, etc. In addition to the decline or even loss of signal quality, the result of brain damage is unacceptable.

The 3D printed polymer technology from Zhao Xuanhe's team can easily make soft neural probes, which can be used in brain-computer interfaces to better fit the shape of the brain and connect with the brain for a longer period of time, while reducing the damage caused by rigid materials to brain tissue.

"Traditionaly, electrodes are rigid metals, and if vibrations occur, these metal electrodes may damage brain tissue," Zhao said, adding that the test results show that flexible materials can be used as neural electrodes instead of rigid metals.

"At the same time, the probe can maintain material properties and functions comparable to those of metal electrodes." According to Cho, the conductive polymer produced by 3D printing has even better bioelectrical properties and electrical properties when in contact with nerves than metals.

In Zhao's view, the production of neural electrodes is a very representative application scenario for the latest research results, reflecting the advantages of materials that are both flexible and conductive.

However, he stressed that this is only an example to demonstrate the properties of the material, not the main aspect of the research work, and the brain-computer interface is not the only application scenario of the material.

When conductive polymers can be manufactured by 3D printing a variety of high-precision, three-dimensional devices and structures, it has a wider application prospect than two-dimensional devices,such as three-dimensional circuits, three-dimensional sensors, three-dimensional catalysts, three-dimensional battery electrodes, etc., from two-dimensional to three-dimensional breakthroughs provide more possibilities for a variety of future devices.

-End-

Reference:

http://news.mit.edu/2020/engineers-3d-print-brain-implants-0330

(https://rdcu.be/b3iT7)