Time:2020-04-16 Reading:17576

First of all, do not

say whether these products contain real graphene, and do not say that there is

no data to support the various magical effects advertised by businesses, these

can at least more or less reflect the public's expectations of graphene, this

magical material.

In fact, in the

field of rigorous scientific research, scholars have been exploring more

possible applications of graphene. For example, can you imagine graphene being

used to 3D print artificial blood vessels? Recently, Alvaro Mata and other

researchers at Queen Mary University of London published a paper in the journal

Nature Communications, reporting a disordered protein and graphene oxide (GO)

co-assembly system, which can form capillary-like structures in a manner

similar to 3D bio-printing. Has some of the physiological properties of blood

vessel tissue, and is expected to be used in the lab to mimic key parts of

human tissues and organs.

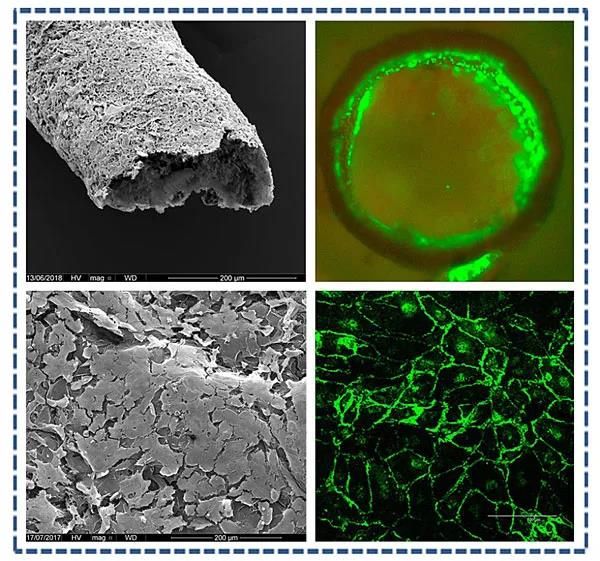

Self-assembly of a

vascular-like structure. Photo credit: Nat. Commun.

GO is rich in

oxygen-containing functional groups (hydroxyl, alkoxy, carbonyl and carboxyl)

and is often electronegative itself, so it can facilitate interactions with

different molecules -especially positively charged ones. The researchers'

choice of recombinamers to interact with graphene oxide is a disordered protein

-Elastin-like recombinamers (ELRs) -which is a class of recombinamers based on

the natural elastin motif Val-Pro-Gly-X-Gly (VPGXG, Where X can beany amino

acid other than proline), resulting in elastin-like peptides. Previous studies

have shown that these polypeptide molecules take on different molecular

conformations with temperature changes, can exhibit reversible phase

transitions, and have been used to make biocompatible materials. The three ELRs

involved in this paper are shown in Figure a below.

Molecular

construction and co-assembly principles. Photo credit: Nat. Commun.

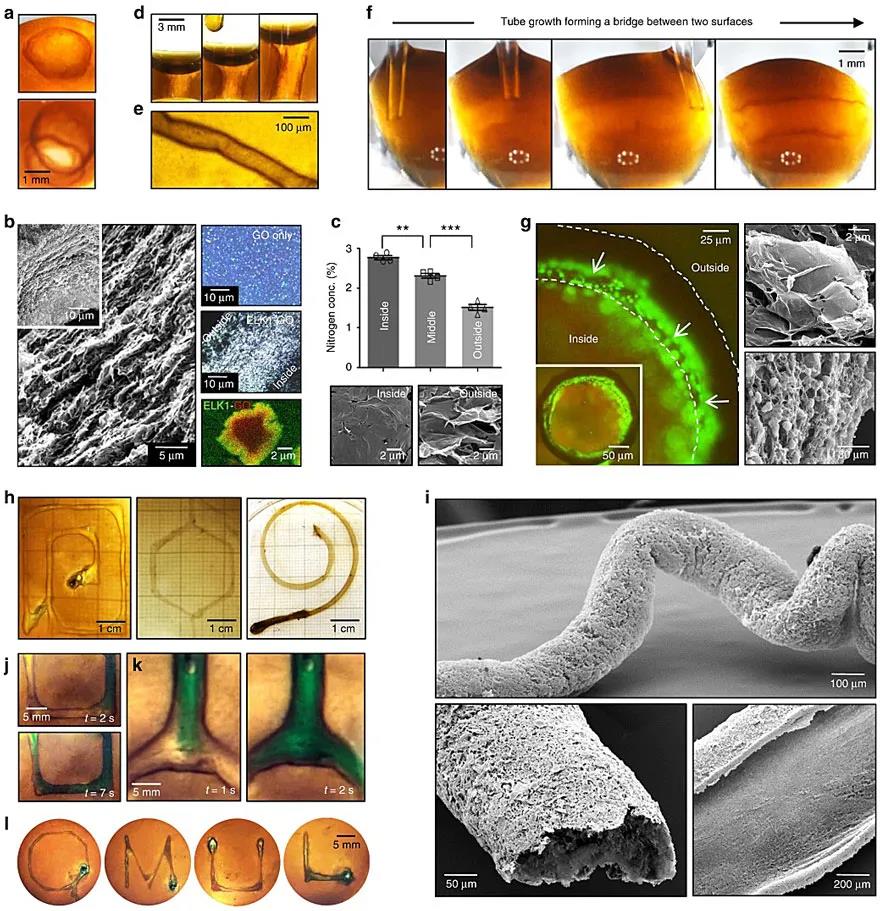

Interestingly, when

the ELK1 solution drops into the GO solution, a multilayer film with a

thickness of ~ 50μm can be formed at the

interface around the droplet. The film is self-assembled by the charge

interaction of ELK1 and GO. Then, as the syringe moves while injecting the ELK1

solution, it can form a tubular structure, whose inner diameter is determined

by the size of the injection needle. The system can form capillary-like

structures through collaborative self-assembly in a culture medium where cells

are present, and the cells can be embedded in and on the wall of the tube.

Self-assembly, structure

and properties of ELK1-GO. Photo credit: Nat. Commun.

If the ELK1 solution

is put into the extrusion 3D printer as "ink", you can freely

"print" different shapes of tubular structures in the GO solution. As

a result, the researchers printed tubes with different inner diameters,

different sizes, different torsion angles and different forks, which can

withstand a water flow of up to 12.5 mL/min for at least 24 hours. The highest

flow rate will produce a shear stress of 0.26 N/m2, which is not far from the

average shear stress generated by the common carotid artery (0.7 N/m2).

Since the reason for

the self-assembly comes from the strong interaction between ELK1 and GO at the

molecular scale, the solution concentration of both will certainly affect the

properties of the resulting tubular structure. The study found that the

interaction was strongest when the concentration ratio of the two was between

15 and 40, so during the "printing" process, the concentration of

ELK1 was maintained at 2%, while the concentration of GO was selected to be

0.05%, 0.10% and 0.15%. As expected, the strength, fracture strain and

toughness of the tubular structure all increased with the increase of GO

concentration. The tubular structures prepared with 0.10% GO solution had the highest

modulus of elasticity.

Molecular

interaction and mechanical properties test of ELK1 and GO. Photo credit: Nat. Commun.

At different

temperatures, the structural properties formed by the co-assembly of ELK1 and

GO are also different. It was found that the tubular structure obtained at the

transition temperature (Tt) of ELK1 at 30 °C

was more stable and clearer than that obtained at 4 °C

and 45 °C,

indicating a stronger interaction between ELK1 and GO at 30 °C.

The 3D conformation of ELK1 at different temperatures plays a key role in its

interaction with the GO sheet, which in turn influences the diffusion-reaction

mechanism that determines the performance of the resulting ELK1-Go tubular

structure.

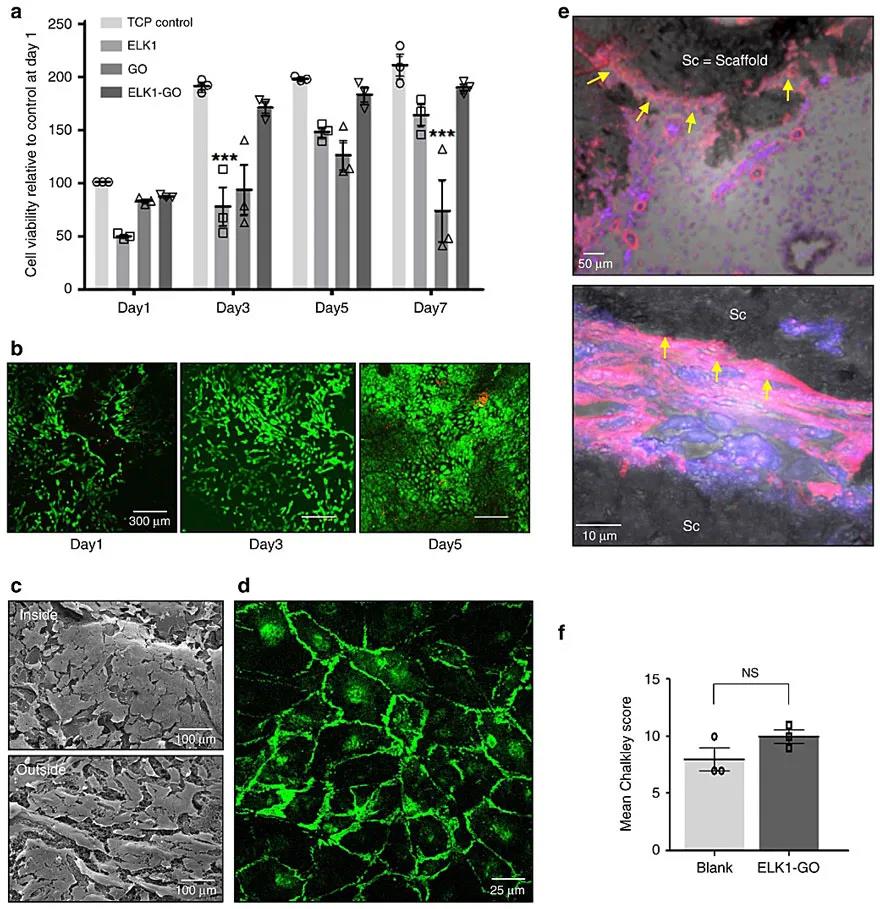

The cytotoxicity and

biocompatibility of ELK1-GO were verified in vitro. Photo credit: Nat. Commun.

"People are

very interested in developing materials and manufacturing processes that mimic

nature. However, the ability to build functional materials and devices through

self-assembly of molecules has been limited ", Yuanhao Wu says [1],

"This study introduces a new method to combine proteins with graphene

oxide through self-assembly, which can be easily combined with manufacturing

techniques to build biofluid devices, Enabling researchers to replicate key

parts of human tissues and organs in the lab."

References:

1. Biomaterial

discovery enables 3D printing of tissue-like vascular structures

https://www.nottingham.ac.uk/news/biomaterial-discovery-enables-3d-printing

Article converted

from X-MOL (x-mol.com)