Time:2020-05-20 Reading:19739

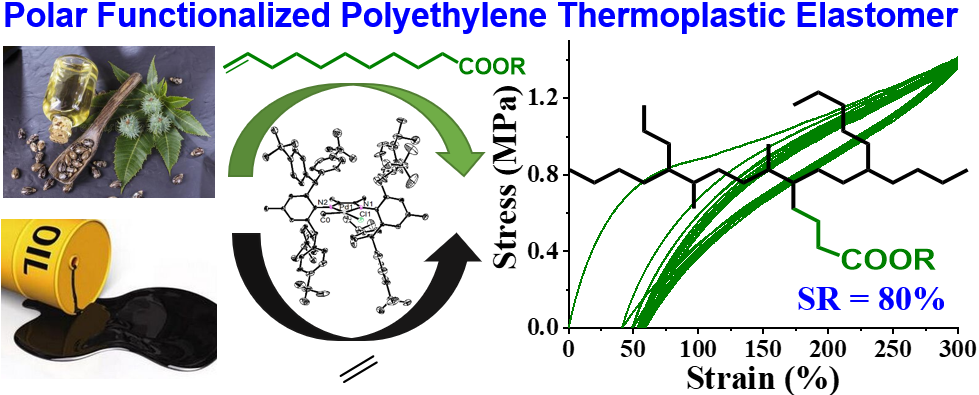

Thermoplastic elastomers (TPE) are a class of

high-molecular materials that can be easily molded, extruded, and reused like

plastics, while also possessing the typical elastic properties of rubber. They

are widely used in industries such as automotive and home appliances. The idea

of synthesizing thermoplastic polyolefin elastomers from ethylene in a single

step is both intriguing and challenging. In recent years, Professor Chen

Changle's research group at USTC (University of Science and Technology of

China) and some colleagues have successfully synthesized polyethylene

thermoplastic elastomers via α-diimine nickel-catalyzed ethylene

polymerization, achieving a series of significant results. Since the α-diimine

palladium catalyst tends to have greater chain walking than nickel catalysts,

it often results in highly branched polyolefins with inferior mechanical

properties, making its use in the preparation and application of thermoplastic

polyolefin elastomers very challenging. In this work, they have, for the first

time, reported the direct synthesis of polyethylene thermoplastic elastomers

catalyzed by an α-diimine palladium catalyst. With precise catalyst design and

polymerization adjustment, high-performance polyethylene thermoplastic

elastomers can be produced (with an elasticity recovery value reaching up to

83%). Most importantly and significantly, polar functionalized polyethylene

thermoplastic elastomers can be prepared through the copolymerization of ethylene

with biomass-derived comonomers, and the resultant polar functionalized

polyethylene thermoplastic elastomers also exhibit excellent elastic properties

(with an elasticity recovery value reaching up to 80%).

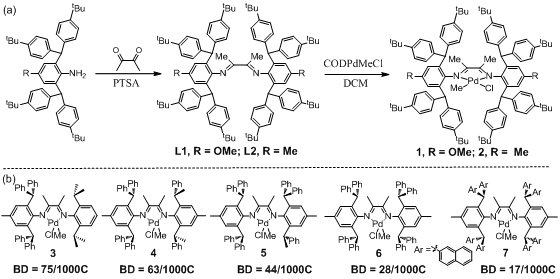

In this study, the research team first prepared a diimine palladium catalyst substituted with a large steric hindrance tertiary butyl group, labeled 1-2. It demonstrates moderate polymerization activity in ethylene polymerization, producing polyethylene with a high molecular weight (Mn up to 45.58 x 104) and a medium branching structure (60/1000C). At the same time, using the reported bulky palladium catalysts 3-7 under the same conditions, they synthesized a series of high molecular weight polyethylenes with varying branch structures (shown in

Figure 2). Additionally,

they utilized catalysts 1-2 to prepare high molecular weight (Mn up to 34.09 x

104) medium branched biomass-functionalized polyethylene, which

retains high activity during copolymerization.

Figure 2. Diimine palladium catalysts prepared in this

study with tertiary butyl substitution and a series of reported bulky diimine

palladium catalysts.

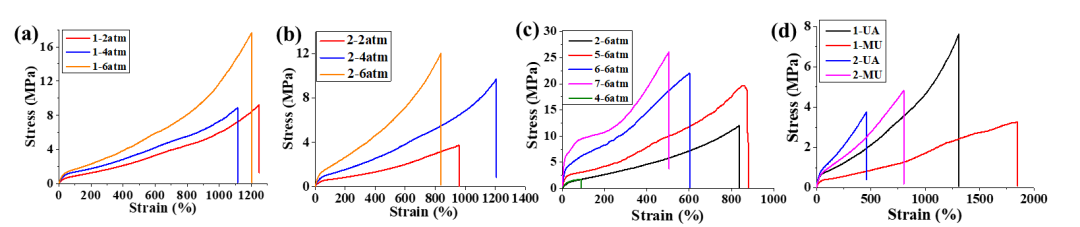

The polymers obtained from the aforementioned catalysts

were first subjected to tensile strength tests (Figure 3). These samples showed

mechanical properties characterized by relatively low break stress values

(3.3-17.6 MPa) and very high strain-at-break values (452% - 1841%). Typically,

under the same other conditions, the breaking stress and Young's modulus

increase with increasing ethylene pressure. This indicates that increasing the

melting point of the polymer or reducing its branching density will increase

the material's ultimate tensile strength and tensile toughness. Meanwhile,

under the same other conditions, polyethylene obtained from catalyst 1 has

higher ultimate tensile strength and tensile toughness than that obtained from

catalyst 2. This is mainly because the electron-rich catalyst 1 can produce

polyethylene with a lower degree of branching and a higher melting point. The

aforementioned experiments show that by merely altering the polymerization

conditions or modifying the electronic effects of the ligands, the mechanical

properties of the resulting polyethylene can be adjusted. For comparison, they

examined polyethylene produced by catalysts 4-6, which displayed very high

breaking stress values (19.6-26.0 MPa) and high strain-at-break values (500% -

860%). This suggests that polymers prepared by catalysts 1-2 have better

elastomeric potential. They further studied the elasticity recovery rate of the

resulting polymers (strain lag tests).

Figure 3. Stress-strain curves of the prepared polyethylene

and polar copolymers.

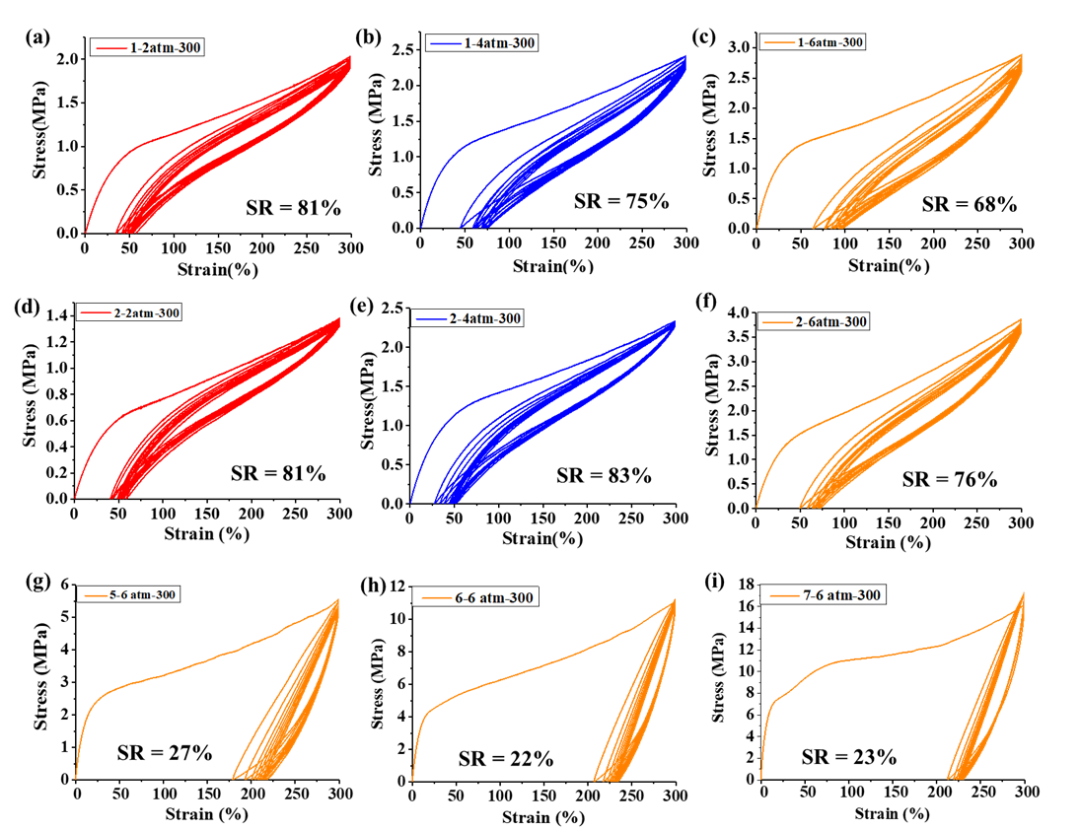

Polyethylene prepared using catalysts 1-2 had an elasticity

recovery rate (SR) of 68% to 83%, comparable to previously reported

polyethylene elastomers obtained through α-diimine nickel catalysts (Figure 4).

In contrast, polyethylene produced by catalysts 5-7 displayed inferior elastic

properties, with SR values of 22% -27% (Figure 4). The polymer's high molecular

weight and the appropriate high branching microstructure (high entropic

elasticity and suitable crystalline ratio) seem to be the primary factors

contributing to their excellent elasticity. Thus, the catalytic system reported

in this study offers an alternative effective route for the synthesis of

thermoplastic polyethylene elastomers. Most importantly, to the best of our

knowledge, this is the first time thermoplastic polyethylene elastomers have

been prepared via an α-diimine palladium system, with most previous preparations

coming from nickel systems. Interestingly, biomass-functionalized polyethylene

prepared by catalysts 1-2 also has excellent elastic properties (SR = 72% -80%)

(Figure 5). The above experimental results indicate that the structure of the

catalyst plays a decisive role in the elastic properties of these polymer

samples.

The related research was published under the title

"Direct Synthesis of Polar Functionalized Polyethylene Thermoplastic

Elastomer" in the journal Macromolecules (2020, 53, 2539-2546). Professor

Dai Shengyu of Anhui University and Professor Chen Changle of the University of

Science and Technology of China were the corresponding authors. This work was

funded by the National Natural Science Foundation of China (NSFC 51703215, 21690071, U19B6001, and

U1904212).

Reference link:

https://pubs.acs.org/doi/10.1021/acs.macromol.0c00083